Material Handling Racks: The Backbone of Efficient Storage and Movement

Material handling racks are essential tools for industries that prioritize organized storage, efficient handling, and seamless transportation of goods. These racks provide a structured system for storing materials, ensuring safety, accessibility, and space optimization. Widely used in warehouses, manufacturing units, and logistics hubs, material handling racks are designed to meet the specific needs of diverse industries.

What are Material Handling Racks?

Material handling racks are storage systems designed to support the movement, protection, and storage of goods throughout the supply chain. They come in various designs and configurations, offering solutions for everything from lightweight items to heavy-duty industrial goods. These racks are integral to managing materials efficiently, reducing handling time, and minimizing damage during storage and transit.

Key Features of Material Handling Racks

- Durability Constructed with high-quality materials like steel or aluminum for long-term use and resilience.

- Customizable Configurations Available in modular designs to cater to different storage needs and layouts.

- Load Capacity Designed to handle varying weight capacities, from lightweight products to heavy machinery.

- Versatility Suitable for various applications, including pallet storage, tool organization, and bulk material handling.

- Safety Features Equipped with robust bracing and locking mechanisms to ensure safety during storage and movement.

- Space Optimization Vertical and horizontal configurations maximize storage space while maintaining accessibility.

Types of Material Handling Racks

- Pallet Racks Designed for storing goods on pallets, commonly used in warehouses and distribution centers.

- Cantilever Racks Ideal for storing long or awkwardly shaped items like pipes, lumber, and rods.

- Drive-In/Drive-Through Racks Allow forklifts to drive into the storage area for high-density storage.

- Push-Back Racks Utilize inclined rails to store goods in a first-in, last-out (FILO) system.

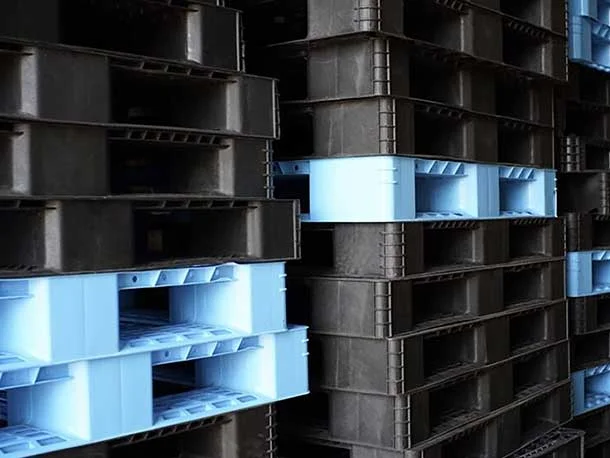

- Stackable Racks Modular racks that can be stacked to maximize vertical storage.

- Roll-Out Racks Feature sliding shelves for easy access to stored items, ideal for tools and dies.

- Bulk Storage Racks Used for storing large quantities of loose or bulk materials.

Applications of Material Handling Racks

- Warehouses Streamline the storage and retrieval of inventory.

- Manufacturing Units Organize raw materials, tools, and finished goods.

- Retail Outlets Display and store products efficiently.

- Automotive Industry Store spare parts, tires, and heavy machinery components.

- Construction Sites Hold tools, construction materials, and equipment securely.