Industrial Loading Racks: A Comprehensive Guide

Industrial loading racks are an essential component of modern warehouses, manufacturing facilities, and distribution centers. Designed to optimize storage and streamline operations, these heavy-duty racks provide a safe and efficient way to store and organize large quantities of materials or products. They are engineered to handle significant loads, ensuring durability and reliability in demanding industrial environments.

What are Industrial Loading Racks?

Industrial loading racks are sturdy and customizable storage systems made from durable materials such as steel. These racks are specifically designed to store heavy and bulk items, offering easy accessibility and efficient use of space. They are commonly used in industries such as logistics, manufacturing, retail, and automotive, where managing large volumes of goods is a priority.

Key Features of Industrial Loading Racks

- High Load Capacity: Designed to handle heavy loads, often exceeding thousands of kilograms per rack.

- Durable Construction: Made from high-strength materials like industrial-grade steel, often with corrosion-resistant finishes.

- Modular Design: Easy to assemble, disassemble, and reconfigure to adapt to changing storage needs.

- Customizable Dimensions: Available in various sizes and configurations to suit specific industrial requirements.

- Optimal Space Utilization: Maximizes storage capacity by utilizing vertical and horizontal space efficiently.

- Safety Features: Includes reinforced frames, safety locks, and secure shelving to prevent accidents.

Types of Industrial Loading Racks

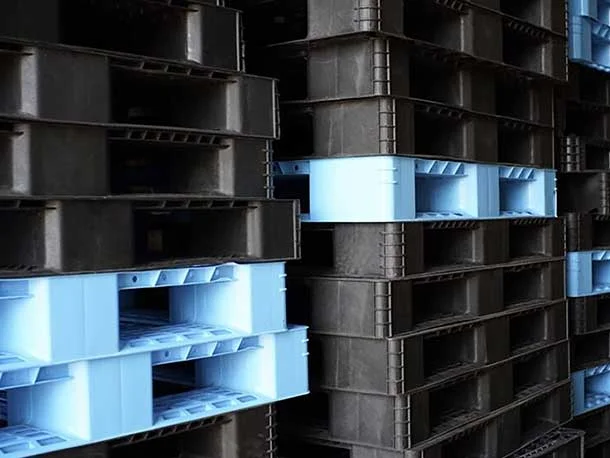

- Pallet Racks: Designed to store palletized goods, these racks are widely used in warehouses and distribution centers.

- Cantilever Racks: Ideal for storing long or bulky items such as pipes, lumber, and rods.

- Drive-In Racks: Provides high-density storage by allowing forklifts to drive directly into the rack structure.

- Push-Back Racks: Enables efficient storage and retrieval using a sliding mechanism for palletized goods.

- Mezzanine Racks: Multi-level racks that maximize vertical space, offering additional storage or work areas.

- Heavy-Duty Shelving: Suitable for storing smaller but heavy items, offering adjustable shelves for versatility.

Benefits of Industrial Loading Racks

- Increased Storage Efficiency: Maximizes available space, allowing businesses to store more goods in the same area.

- Enhanced Organization: Simplifies inventory management by providing clear and systematic storage solutions.

- Cost-Effective: Durable and long-lasting, reducing the need for frequent replacements.

- Improved Safety: Minimizes risks of accidents by securely storing heavy and bulky items.

- Customizable Options: Tailored solutions to meet the unique requirements of different industries.

- Quick Accessibility: Facilitates faster loading and unloading, improving operational efficiency.